Development of Predictive Maintenance and Machine Status Monitoring on Back Part Molding Machine used in Shoe Manufacturing

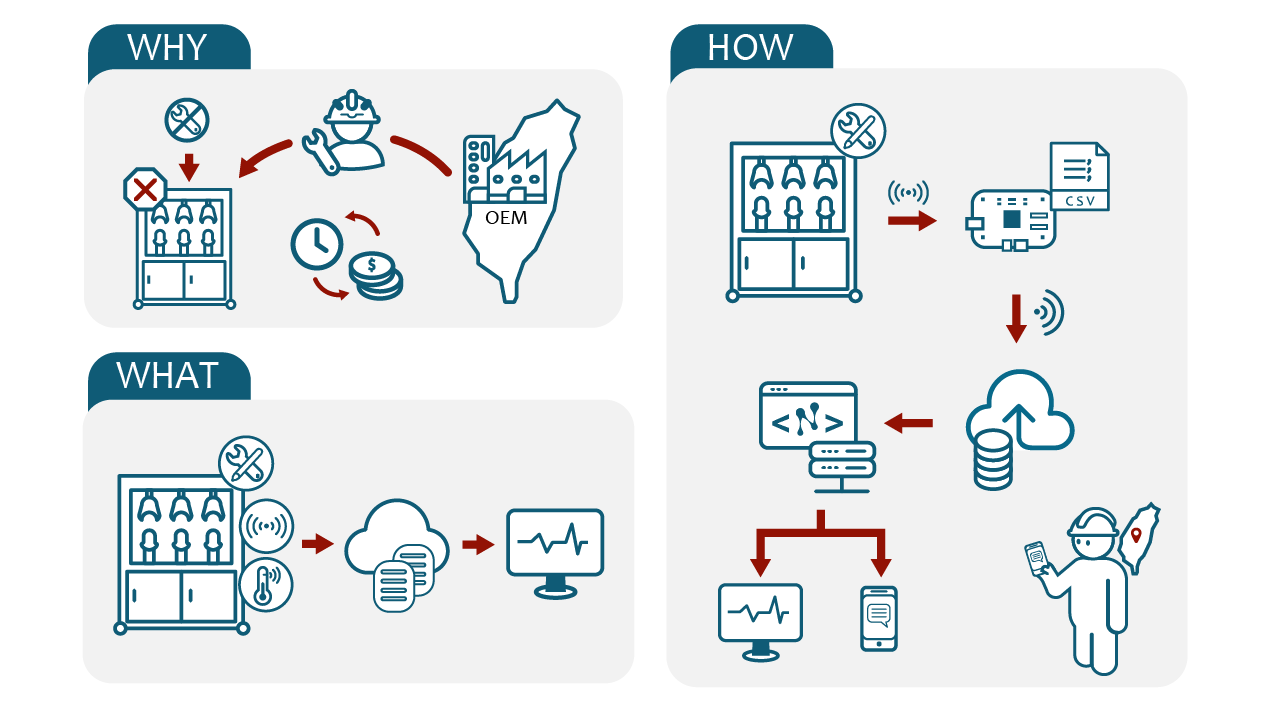

Today approximately 70% of all machinery used in shoe factories worldwide is produced in Taiwan. It is common within the shoe industry to neglect maintenance and call upon the machine vendor when a machine breaks down and request the vendor to send an engineer to repair it. This irregular maintenance is challenging and expensive for the vendors, since over 90% of all machines are exported. Together with a shoe machine vendor—New Yu Ming Machine Corporation (NYM)—we set out to make a case study of how a machine upgrade using Internet of Things (IoT) and Industry 4.0 related technology could enable remote monitoring. This could potentially decrease the number of unscheduled maintenance visits overseas.

We focused on cost efficient upgrading of one type of shoe production machine—the NYM Back Part Molding machine (BPM), which is used to attach the back part of shoes. After having studied the existing machine design and looked at commercial IoT options, we decided that the simplest and cheapest option for this case study is to connect a computer to the Programmable Logic Controller (PLC), which already was interfaced to all sensors. We made the computer upload all sensor data to a cloud database and used a cloud server to implement a dashboard for remote Machine Status Monitoring (MSM) and a real-time set point triggered email alert for Abnormal Condition Detection (ACD) to operators to enable a form of Predictive Maintenance (PdM).

We successfully implemented and demonstrated a Software as a Service (SaaS) solution for MSM and PdM on a BPM and transferred this knowledge to NYM. We have identified several challenges of an industry-wide upgrade, such as data ownership and sharing, lack of Data Scientists, and the need of a new business model. To stay internationally competitive, the shoe manufacturing industry need to overcome these and we propose a roadmap for this.

Keywords: Shoe machine, Industry 4.0, PLC, Machine status monitoring, Internet of things, email alert

發展用於製鞋背部造模機的預測性維護與機器狀態監控

台灣是製鞋機大國,台灣生產的鞋機器有90%以上外銷,全球市占率70%,生產數量為世界第一,這些機台在國外生問題且製鞋廠商無法解決時,常要從台灣派遣工程師至當地進行故障排除,耗時費力且消耗成本。若能建立即時的遠端機台狀況監控,並在機台出現異常時能即時通知警告,可大幅縮短反應時間並節省成本。此專題與裕銘機械有限公司合作,使用其旗下產品後踵定型機為實驗機種,希望能建立即時遠端預警系統。

我們引入工業4.0的概念設計一套物聯網系統,將機台上感測器的資料上傳至雲端空間中儲存,並提供網頁介面讓使用者能夠即時存取並監看機台狀況,同時系統會根據這些資料主動偵測異常狀況,當機台發生異常時發送通知訊息通知使用者,以達到即時監控的目的。 本系統可有效降低鞋機廠的人事成本,且此系統可運用至其他PLC based之機台,並可將異常狀況檢測替換成其他更複雜的模型,以提供更進階之功能,如機台的預測保養。

關鍵字: 製鞋機、工業4.0、物聯網、雲端服務、即時監控異常檢測、自動通知、PLC

Principal Investigator: Ass. Prof. Torbjörn Nordling

Sponsor: Ministry of Economic Affairs in Taiwan

Grant Identifier: PS105130241

Duration: 2016-05-01 to 2016-10-31

Members: Evan Wu, Daniel Chen, Shun-Jie Zhang, Torbjörn Nordling.